LDAR (Leak Detection and Repair) has now reached beyond chemical and O&G processing plants to the O&G upstream and midstream facilities with the release of 40 CFR Part 60 Subpart OOOOa on June 3, 2016 (effective August 2, 2016).

The leak detection rules directly affect well sites and compressor stations constructed, modified, or reconstructed after September 18, 2015. This means that any new well completion operation following hydraulic fracturing or refracturing or the increase in horsepower at a compressor station immediately subjects the well site or compressor station to the rules. And like Quad O, the “once in, always in” applies and there are no loop holes this time.

EPA defines a fugitive emission source as a facility that has the potential to emit fugitive emissions of methane or VOCs, including and not limited to flanges, open-ended lines, connectors, PSVs, valves, compressors, instruments, and meters. This is a good old fashioned, “catch-all” clause.

No worries! OTA is here to help! We’ve invested in your future with the most innovative leak detection equipment on the market with the FLIR GF320 optical gas imaging (OGI) camera. This slashes the survey inspection time by more than a 1/4th of the time of the alternative Method 21 approach. And if that does not scream money savings, we are offering up our repair services during the inspection. This will save you even more time and money because we can conduct the mandatory re-survey on the day of the initial survey, which means you don’t have the added cost of a return visit.

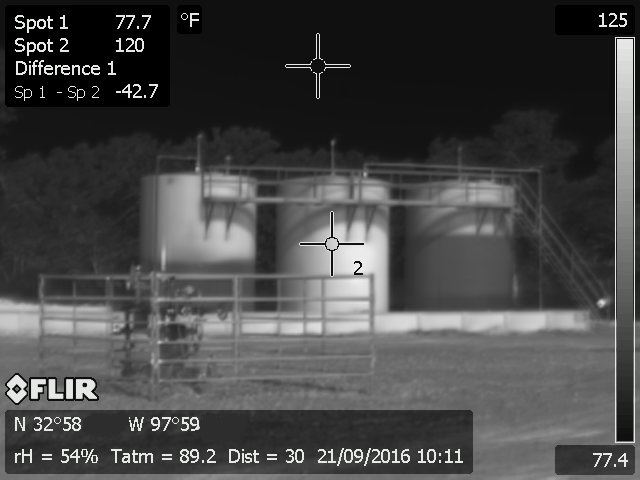

We’ve all seen those videos depicting vapors venting from thief hatches and vent valves, but did you know that you can utilize the same camera to view inside of enclosed vessels and determine liquid levels and gas caps (see below)?

MONITORING FREQUENCY

Well Sites (semiannual) & Compressor Stations (quarterly)

Don’t forget about your monitoring plan. Per 60.5397a (b) each operator must develop a plan for the surveyor to follow and it must cover the collection of all fugitive emissions components.

You’re in luck! OTA has already developed the plan for you!

Operators have until June 3, 2017 to conduct initial surveys of all affected well sites and compressor stations, but don’t let that time frame put you too much at ease because one of the most common leaks found are from compressor rod packings. This takes a highly trained technician all day to replace packings, and this must be done within thirty (30) days from leak discovery per 60.5397a (h)(1). Now, add up how many lease compressors that you have in your fleet, then consider the leases from everyone else and we easily run into longer than 30 day repair lead times.

Ask us about our Pre-Survey inspection and how this can save you even more money and time before the reportable LDAR survey.

To ask us more about our Quad Oa and LDAR services, contact the head of our environmental department at enviro@otacompression.com. Have any air permitting questions? Contact our air permit expert at lvasquez@otacompression.com.